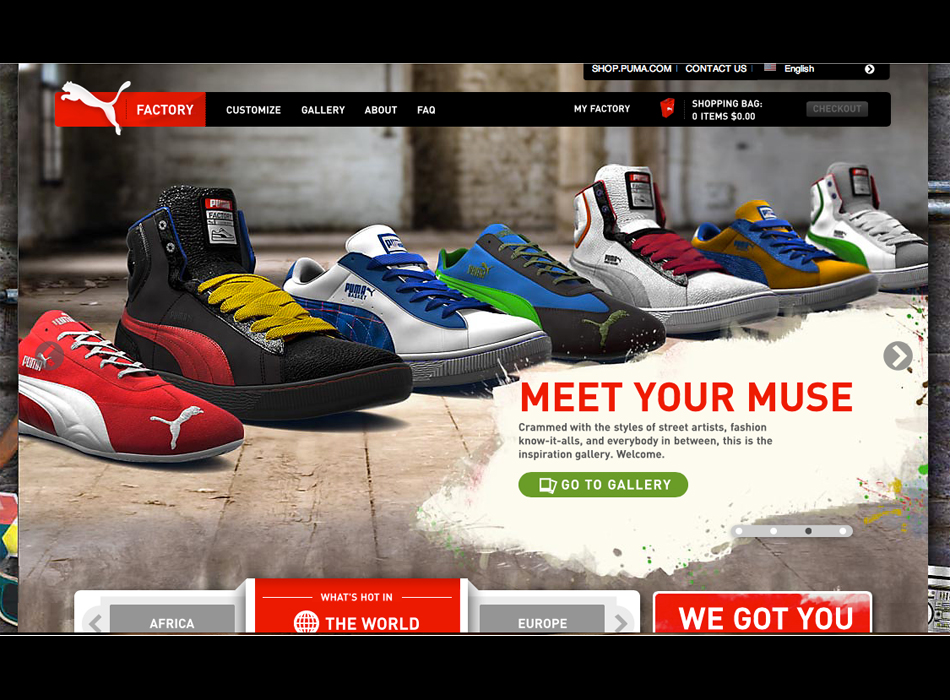

PUMA Factory

The PUMA Factory project relaunched a dormant line of business for PUMA. PUMA was early to market with a shoe customization platform called Mongolian Barbecue, launching it prior to Nike's successful NikeID platform. The platform allowed for shoe customization and was widely promoted. You could even create shoes by ordering Mongolian BBQ at W Hotels, and having a cart brought up to you with all the shoe parts on it. However, the platform faced several operational problems between order and fulfillment. Customers often received the wrong shoe configurations after waiting up to 6 weeks for their orders. In the worst cases, customers received empty shoe boxes. PUMA hired KBS+ to help rectify the problem, and refresh the old platform.

Our goals when creating the platform were to create:

- A social shopping experience where consumers can show off their creativity

- An intuitive non-linear configuration process

- A seamless operational system for PUMA's internal constituents and partners

- Create a global platform for the PUMA Factory business

Creating a social shopping experience meant elevating configuration to a creative act by allowing users to share to a gallery, receive kudos, and eventually sell designs in their own boutique (still to come). For the configuration portion of the site we made several prototypes that allowed us to iteratively refine the design.

As one of the major goals of the platform was operational simplicity, we spent a lot of time creating a system that would work for the factory and all our partners. To conduct workflow research, I made several trips to the Factory in Dongguan, China to map out the existing workflow with the factory and shipping partners. Using this knowledge we mapped the workflow from order to the customer's door — and even as far as returns. This map allowed us to design interfaces and printed documentation that would work for factory workers, factory operations staff, customer service, and program admin staff.

As the program expands we wanted to make sure the technical architecture of the platform would support its growth. As such it was built with a service oriented architecture that abstracted the business logic and partner integrations from the front-end interfaces and connected the the two through a series of web services. Globalization is also handled through this infrastructure with each individual country store tying to the same set of services. When PUMA decides to make an 10-foot configuration experience or change shipping partners they will only have to write isolated blocks of code to make the changes.

As the product architect on the project, I:

- Mapped PUMA's workflow from order to customer

- Worked with PUMA to select partners for shipping, payment, and tax services

- Designed the technical architecture of the platform

- Worked with a UX designer to design the interfaces and conduct user research

- Conducted factory workflow research

- Worked as part of the project leadership team

You can visit the US site here.